- Contact Us

- -

- USD

Knowledge Center · 2025-09-04 14:24:17 · 968 hits

The module (m) is defined by ISO as the unit used to indicate the size of a gear tooth.

For gears to mesh properly, they must be paired with gears that have the same module.

In a correctly meshing pair of gears, the modules are identical.

The pitch (p) refers to the distance between two adjacent teeth. A larger pitch means bigger teeth, while a smaller pitch corresponds to smaller teeth. Thus, the pitch directly reflects the size of the teeth.

The pitch circle of a gear is equivalent to the outer circumference of a friction wheel—essentially, it’s the reference circle from which the pitch of the gear is determined.

The circumference of the pitch circle (πd) is calculated by multiplying the diameter of the pitch circle (d)—which is also known as the pitch circle diameter—by the mathematical constant π (approximately 3.1415…). The pitch itself can then be derived by dividing the pitch circle’s circumference by the number of teeth (z):

p = πd / z

However, since the pitch includes the value of π (approximately 3.1415…), this calculation can become quite complex.

To simplify the process, we divide the pitch by π, resulting in d/z. This result is officially called the "module" and serves as the standardized unit for expressing tooth size:

m = d / z

While the pitch circle diameter is measured in millimeters (mm), dividing it by the number of teeth yields a module value that is also expressed in mm. Yet, in practical applications, the unit "mm" is typically omitted when referring to the module; instead, it’s commonly written as m1, m2, m4, and so on, with numbers following the "m" designation.

Additionally, just like the pitch, a larger module value indicates significantly larger teeth.

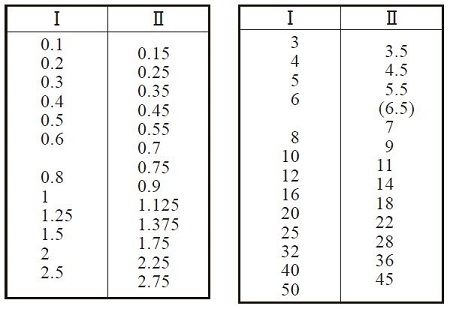

In JIS specifications, standard values for the module used in spur and helical gears for general and heavy-duty machinery are specified (Table 1), recommending the use of modules from Column I whenever possible, while also advising against the use of module 6.5 whenever feasible.

As mentioned above, ISO specifies the use of the module as the unit for indicating gear tooth size; however, countries like the United States, which traditionally use inches as their length unit, often prefer to work with diametral pitch (DP).

Additionally, circular pitch (CP) is also employed in some cases. (By setting the circular pitch to an integer value, it becomes easier to ensure that the transmission distance of the mechanism remains an integer.)

Table 2 compares the module (m), circular pitch (CP), and diametral pitch (DP).

| Module m | circular pitch CP | diametral pitch DP |

|---|---|---|

| 0.39688 | 1.24682 | 64 |

| 0.5 | 1.57080 | 50.8 |

| 0.52917 | 1.66243 | 48 |

| 0.6 | 1.88496 | 42.33333 |

| 0.79375 | 2.49364 | 32 |

| 0.79577 | 2.5 | 31.91858 |

| 0.8 | 2.51327 | 31.75 |

| 1 | 3.14159 | 25.4 |

| 1.05833 | 3.32485 | 24 |

| 1.25 | 3.92699 | 20.32 |

| 1.27000 | 3.98982 | 20 |

| 1.5 | 4.71239 | 16.93333 |

| 1.59155 | 5 | 15.95929 |

| 1.58750 | 4.98728 | 16 |

| 2 | 6.28319 | 12.70 |

| 2.11667 | 6.64970 | 12 |

| 2.5 | 7.85398 | 10.16 |

| 2.54000 | 7.97965 | 10 |

| 3 | 9.42478 | 8.46667 |

| 3.17500 | 9.97456 | 8 |

| 3.18310 | 10 | 7.97965 |

| 4 | 12.56637 | 6.35 |

| 4.23333 | 13.29941 | 6 |

| 4.77465 | 15 | 5.31976 |

| 5 | 15.70796 | 5.08 |

| 5.08000 | 15.95929 | 5 |

| 6 | 18.84956 | 4.23333 |

| 6.35000 | 19.94911 | 4 |

| 6.36620 | 20 | 3.98982 |

| 8 | 25.13274 | 3.175 |

| 8.46667 | 26.59882 | 3 |

| 10 | 31.41593 | 2.54 |

Table 2 - Pitch Comparison Chart